A tiny custom screw: the issues Apple will face if it moves iPhone assembly back to America

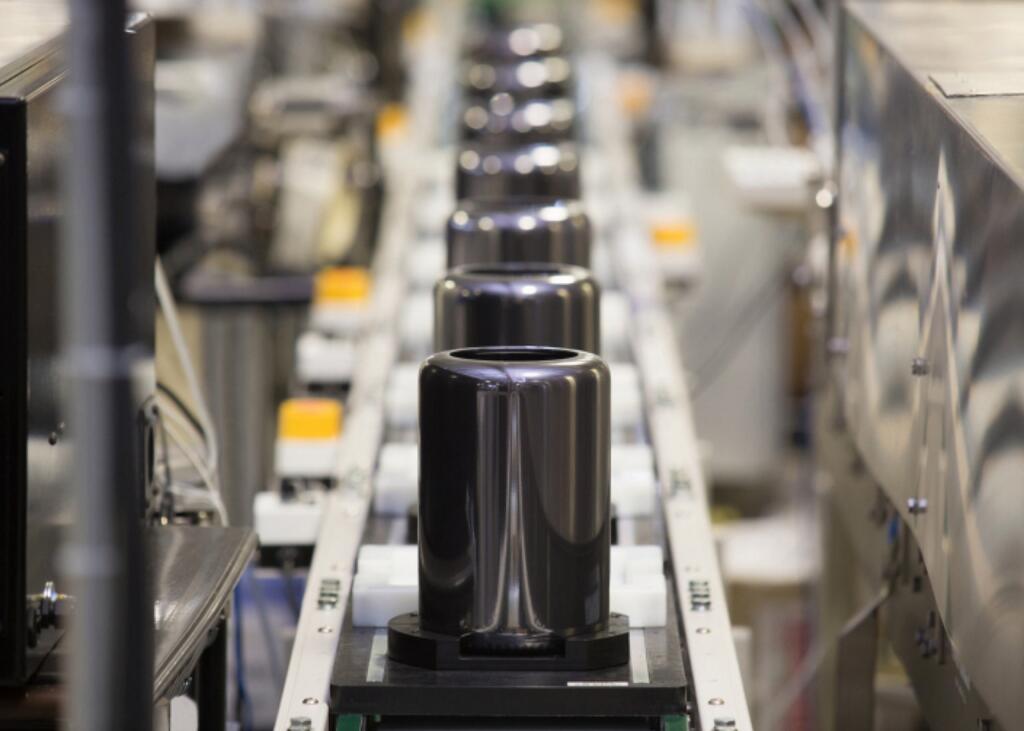

The vast bulk of iPhones too Macs are manufactured too assembled inwards Cathay hence when Apple inwards 2012 announced that its partner Flextronics would arrive at the Mac Pro chassis at its manufacturing flora on the outskirts of Austin, Texas, some people were expectedly skeptical.

The society shifted most of its domestic hardware production to unusual manufacturing inwards 2004, a motility led past times the company’s too hence operations principal Tim Cook.

According to a New York Times even out published this morning, despite the US-China merchandise state of war too Trump’s calls for Apple too other major US applied scientific discipline companies to convey their manufacturing closer home, that’s unlikely to happen.

A tale of a tiny screw illustrates why.

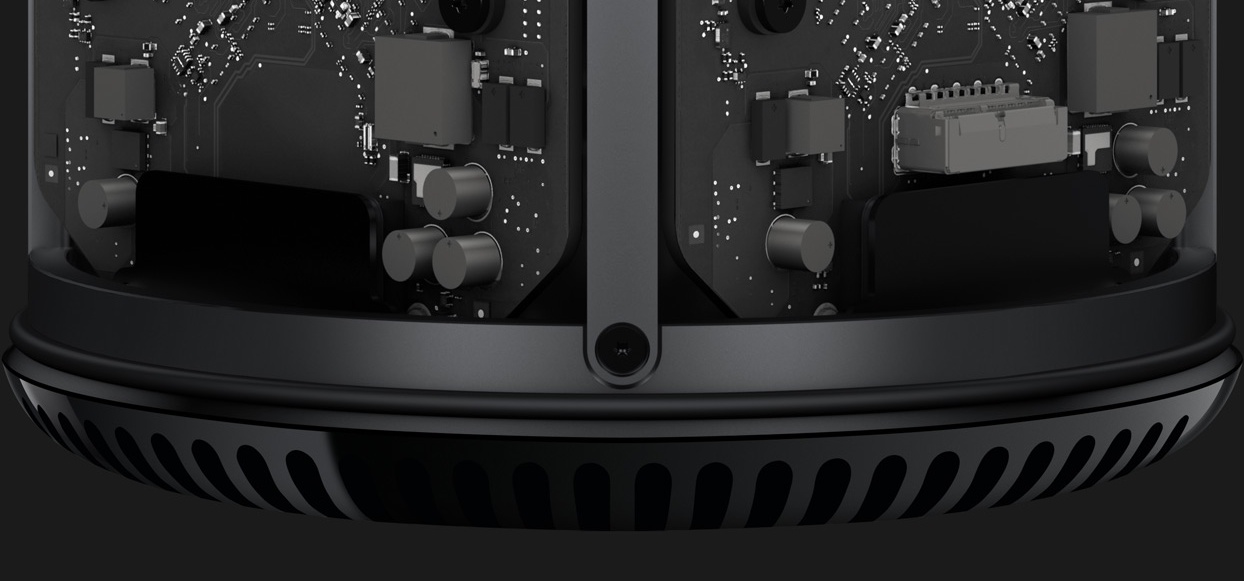

In 2012, Apple’s principal executive, Timothy D. Cook, went on prime-time goggle box to denote that Apple would brand a Mac estimator inwards the United States. It would survive the start Apple production inwards years to survive manufactured past times American workers, too the top-of-the-line Mac Pro would come upward amongst an unusual inscription: ‘Assembled inwards USA.’

But when Apple began making the $3,000 estimator inwards Austin, Texas, it struggled to notice plenty screws, according to iii people who worked on the projection too spoke on the status of anonymity because of confidentiality agreements.

You would intend that finding plenty screws shouldn’t survive a work for an industrial land similar the United States, but goose egg tin sack acquit upon huge manufacturing plants inwards Cathay that tin sack arrive at vast quantities of custom screws on curt notice.

Tests of novel versions of the estimator were hamstrung because a 20-employee machine store that Apple’s manufacturing contractor was relying on could arrive at at most 1,000 screws a day.

The screw shortage was 1 of several problems that postponed sales of the estimator for months, the people who worked on the projection said. By the fourth dimension the estimator was cook for volume production, Apple had ordered screws from China.

Apple, similar other major applied scientific discipline players, has only realized that no solid soil is able to tally China’s combination of scale, skills, infrastructure too cost.

The minimum wage inwards Zhengzhou, China, abode of the world’s biggest iPhone factory, is roughly $2.10 an hour, including benefits. Apple said the starting pay for workers assembling its products at that spot is most $3.15 an hour. Compensation for similar jobs inwards the USA is significantly higher.

And that, my friends, is what you lot teach amongst the electrical flow organisation that priorities maximizing shareholder value at at all cost—even to the detriment of the American worker.

A onetime Apple managing director said:

The Flextronics squad had also been far smaller than what he typically constitute on similar Apple projects inwards China. It was unclear precisely why the projection was understaffed, the managing director said, speculating that it was because American workers were to a greater extent than expensive.

The managing director said similar Apple jobs inwards Cathay would include a roomful of people working to ensure that all materials were inwards identify for production. In Texas, it was 1 worker, who oft seemed overwhelmed, the managing director said.

As a result, materials were regularly out of identify or late, contributing to delays. Another frustration amongst manufacturing inwards Texas: American workers won’t run just about the clock. Chinese factories accept shifts working at all hours, if necessary, too workers are sometimes fifty-fifty roused from their slumber to encounter production goals.

Needless to say, that was non an selection inwards Texas.

The study adds that the concluding assembly is the most labor-intensive business office of edifice applied scientific discipline products, too its place oft determines a product’s solid soil of root for tariffs.

Apple is currently exploring ways to get together some of its products inwards Bharat too Vietnam. In India, for instance, it late began edifice the iPhone 6s handsets (in add-on to “Assembled inwards India” iPhone SE units), according to a recent study inwards The Economic Times.

TUTORIAL: How to bypass article paywalls

While Apple similar a shot produces ii iPhone models locally inwards India, that’s a far cry from those busy factories inwards Cathay that churn out millions of Apple gadgets every month.

Put simply, those manufacturing jobs are never coming dorsum abode due to non exclusively costs involved but also the technical skills, expertise too China’s vast furnish chain.

“In the US, you lot could accept a coming together of tooling engineers too I’m non certain nosotros could create total the room,” Tim Cook said inwards 2017. “In China, you lot could create total multiple football game fields.”

In December, Apple said it would add together upward to 15,000 workers inwards Austin, just miles from the Mac Pro plant. However, none of the novel jobs are expected to survive inwards manufacturing.

And that’s the reality of it, really.

What arrive at you lot brand of this report?

Let us know past times leaving your thoughts inwards the comment section.

0 Response to "A tiny custom screw: the issues Apple will face if it moves iPhone assembly back to America"

Post a Comment